Advanced Dry Ice Block Machine for Dry Ice Production

Dry ice block machine has three different models, the minimum capacity is 120kg/h, the maximum is 500kg/h. The density of dry ice block is 1450-1550kg/m³. Fianal block specification: Length: 125cm, thickness is adjustable: 10-70mm.

Stop letting equipment failures and high operating costs erode your profits. The new generation of Shuliy dry ice block machines, now fully upgraded with Siemens PLC, Schneider electronics, and Omron relays, is engineered for maximum stability and efficiency. Achieve non-stop production, higher yields, and a faster return on your investment. Explore how our technology can revolutionize your dry ice production.

Shuliy dry ice block machines are available in a variety of different sizes and can produce 120 -500kg of dry ice cubes per hour, any dry ice plant can use them. If you need one please contact us now.

The Power of World-Class Components: Your Guarantee of Unmatched Reliability

In today’s competitive market, every minute of production counts. Downtime isn’t just an inconvenience; it’s a direct loss of revenue. That’s why we didn’t just build a dry ice block manufacturing machine; we engineered a production powerhouse. We’ve strategically fortified our equipment with globally recognized, top-tier electrical components. This isn’t just an upgrade; it’s our commitment to your uninterrupted success.

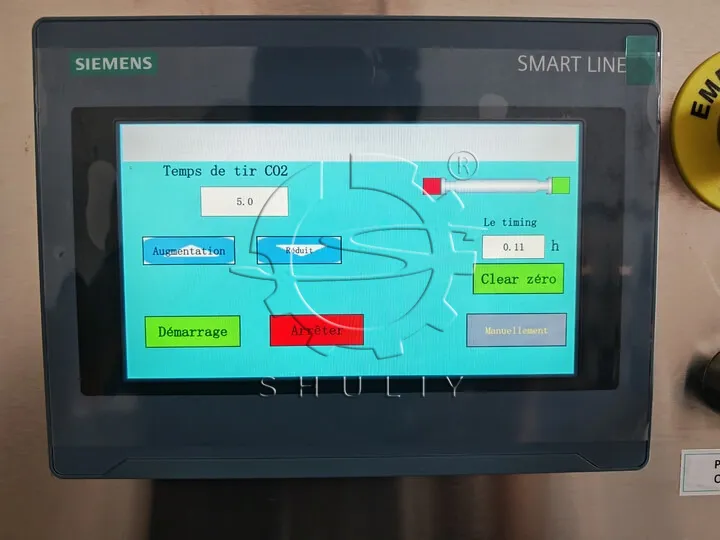

Siemens: The Intelligent Brain of the Operation

dry ice machine Siemens screen

Siemens screen

Siemens screen

At the core of our machine lies the Siemens PLC (Programmable Logic Controller) and HMI Touch Screen. As the machine’s central nervous system, it orchestrates every command with flawless precision.

- Flawless Stability: Say goodbye to frustrating system crashes and random production halts. The Siemens PLC is renowned for its rock-solid stability, ensuring your machine runs smoothly, shift after shift.

- Unparalleled Precision: Effortlessly control the exact weight and size of every dry ice block through the intuitive touch screen. This consistency guarantees product quality and enhances customer satisfaction.

- Simplified Operation: The user-friendly interface reduces operator training time and minimizes the chance of human error, directly lowering your operational costs.

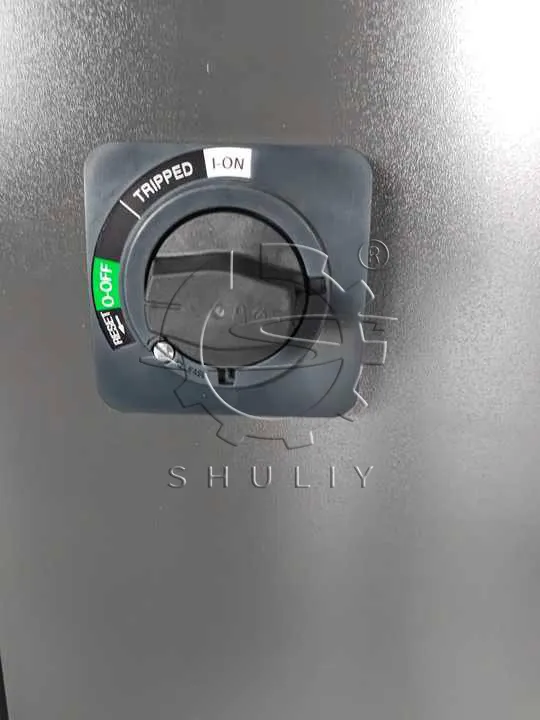

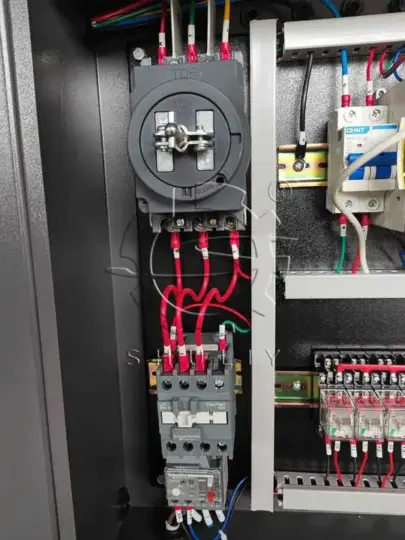

Schneider Electric: The Resilient Heart of Power and Protection

Schneider knob

Schneider knob circuit breaker

Schneider knob circuit breaker

We entrust the critical tasks of power management and equipment protection to Schneider Electric Contactors and Circuit Breakers. This is the robust heart that powers your dry ice block production and shields your investment.

- Extreme Durability: Engineered for millions of cycles, Schneider components easily withstand the demanding, high-frequency start-stop cycles of continuous dry ice production, promising a longer machine lifespan.

- Proactive Protection: It actively safeguards your most valuable asset—the main motor—from overloads and short circuits. This proactive defense prevents catastrophic failures and costly repairs.

- Reduced Maintenance: By using components that are built to last, we dramatically reduce your maintenance needs and the unexpected downtime that comes with inferior parts.

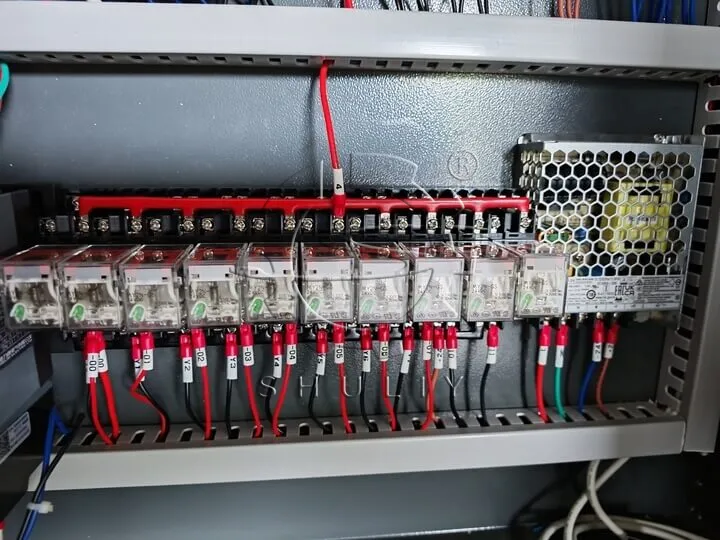

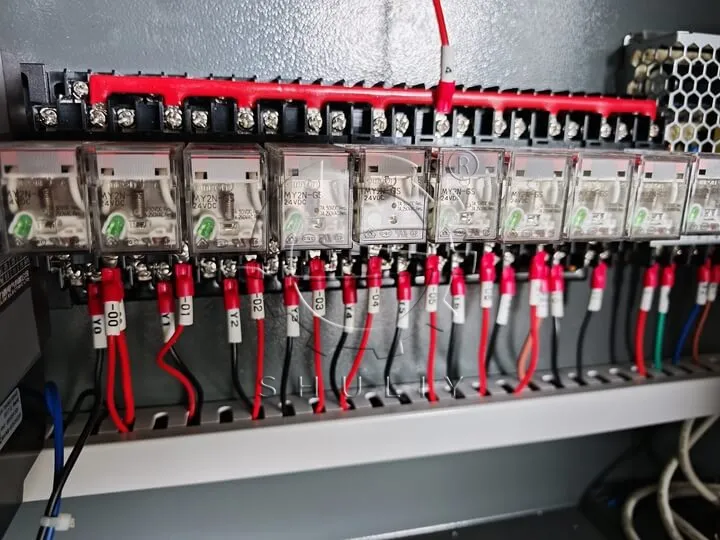

Omron: The Flawless Nervous System for Signal Transmission

Omron intermediate relay

Omron intermediate relay

Omron intermediate relay

Every command from the “brain” (Siemens PLC) is transmitted to the “muscles” (hydraulic valves, motors) via Omron Intermediate Relays. They are the machine’s high-speed nervous system, ensuring every action is instant and accurate.

- Zero-Delay Accuracy: Omron relays provide instantaneous, error-free signal transmission. There are no delays, no missed signals, just perfect execution.

- Perfect Synchronization: This accuracy ensures every mechanical action—from CO₂ injection to compression and ejection—is perfectly synchronized. The result is smoother operation and higher overall efficiency.

- Consistent Quality: Flawless signal transmission contributes directly to the consistency of your final product, ensuring every block of dry ice meets the same high standard.

SL-120 Dry Ice Block Making Machine Working Video

SL-500 Dry Ice Brick Machine Working Video

What Is the Dry Ice Block Production Process?

The dry ice block production process is easy to understand.

- Liquid carbon dioxide introduction: first, liquid carbon dioxide is introduced into the compression chamber of the block dry ice machine through piping.

- Compression: In the compression chamber, the liquid carbon dioxide is compressed to a high pressure.

- Heat transfer cooling: The high pressure liquid carbon dioxide passes through the heat transfer unit where the temperature is gradually reduced to near or below -78.5 degrees Celsius.

- Decompression transformation: When the temperature of the liquid carbon dioxide reaches a critical temperature, it rapidly transforms into solid dry ice.

Why Shuliy? Advantages That Directly Drive Your Profitability

Choosing the right machine is an investment in your business’s future. Our dry ice block making machines are engineered with distinct advantages designed not just to produce dry ice, but to make your entire operation more profitable, reliable, and competitive.

1. Industry-Leading Conversion Rate (>43.5%) for Maximum Profit

In the dry ice business, every drop of liquid CO₂ counts. Our meticulously engineered hydraulic press and optimized cooling system achieve an exceptional conversion rate of over 43.5%, significantly higher than the industry average.

What this means for you: You produce more sellable dry ice from the same amount of liquid CO₂, directly lowering your raw material costs and maximizing your profit margin on every single block. Less waste means more money in your pocket.

2. Built to Last with Food-Grade 304 Stainless Steel

Your investment is built for the long haul. The entire machine body, compression chamber, and all parts in contact with CO₂ are constructed from heavy-duty, food-grade 304 stainless steel.

What this means for you: Superior durability and resistance to corrosion from carbonic acid ensure a longer machine lifespan. It also guarantees full compliance with the strictest hygiene standards, making your product safe for food, medical, and pharmaceutical applications.

3. Safe & Simple: True One-Button Automation

We believe powerful machinery should also be simple to operate. Powered by the intelligent Siemens PLC system, the entire production cycle—from start-up to shutdown—is managed with a single button press.

What this means for you: Drastically reduced training time and costs. It minimizes the need for highly skilled operators and virtually eliminates the risk of costly human error, creating a safer and more efficient work environment.

4. Customized Solutions to Dominate Your Market

Your market is unique, and your product should be too. Our dry ice block machines offer exceptional flexibility, allowing you to easily adjust the block thickness from 10mm to 70mm directly on the touch screen.

What this means for you: The ability to produce various weights and sizes on demand. Whether you’re serving cold chain logistics, industrial cleaning, or event catering, you can deliver the exact product your clients need, giving you a powerful competitive edge.

Find Your Perfect Fit: SL-KZ Series Technical Specifications

Our SL-KZ series dry ice block machine offers a range of capacities to perfectly match your production needs, from small-scale operations to large industrial plants. All models are equipped with our premium electrical configuration for ultimate reliability. Compare the models below to find your ideal solution.

| Specification | SL-KZ-120 | SL-KZ-240 | SL-KZ-500 |

|---|---|---|---|

| Capacity | 120 – 180 kg/h | 240 – 280 kg/h | ~ 500 kg/h |

| Control System | Siemens PLC & HMI Schneider Electric Omron Relays | Siemens PLC & HMI Schneider Electric Omron Relays | Siemens PLC & HMI Schneider Electric Omron Relays |

| Conversion Ratio | ≥ 43.5% | ≥ 43.5% | ≥ 43.5% |

| Dry Ice Block Size | 125 x 105 x (10-70) mm | 125 x 105 x (18-70) mm | Customizable |

| Dry Ice Density | 1450 – 1550 kg/m³ | 1450 – 1550 kg/m³ | 1300 – 1500 kg/m³ |

| Total Power | 4 kW | 7.5 kW (Typical) | 13.5 kW |

| Dimensions ( L×W×H) | 136 x 65 x 140 cm | Contact for details | 270 x 150 x 180 cm |

| Weight | 350 kg | Contact for details | 4500 kg |

Note: All specifications are subject to change based on continuous product improvement. Dry ice block size and other parameters can be customized to meet specific client requirements.

Unsure which model is right for you?

Choosing the correct capacity is crucial for optimizing your return on investment. Our technical experts are ready to help you analyze your production volume, operational needs, and future growth plans to recommend the most cost-effective solution for your business.

Application of Industrial Dry Ice Machine for Block Dry Ice Production

Food refrigeration and transportation: Dry ice is commonly used in the food industry for refrigeration, freezing and transportation of perishable food products such as ice cream, seafood and frozen meats, providing a prolonged cryogenic effect to maintain the freshness of the food.

Healthcare: In the medical field, dry ice is used to cryopreserve biological samples, vaccines, and pharmaceutical products.

Creating smoke effects: Due to the white smoke-like gas produced by dry ice, it is often used in special effects and stage performances.

More Than a Manufacturer: Your Partner in Production Success

We are a reliable dry ice machine manufacturer in China with more than 20 years of professional manufacturing experience. Our machines have been successfully exported to Russia, Saudi Arabia, the United States and many other countries, and we have received favorable comments from our customers. Except dry ice block machine, dry ice pelletizer and blaster are also helped our clients started their business.

We understand that purchasing a machine is a significant investment. That’s why we offer a comprehensive, 360-degree service commitment to ensure you get the maximum value and complete peace of mind, from your first inquiry to years of profitable production.

- Expert Pre-Sale Consultation: Our engineers work with you to analyze your needs and recommend the perfect machine model, ensuring you don’t overspend or under-provision.

- Seamless Installation & Training: We handle everything from professional installation to comprehensive on-site training for your team, guaranteeing a smooth start-up and immediate productivity.

- Rapid Post-Sale Support: Our promise of reliability is backed by a robust warranty, a rapid-response support team, and a fully stocked inventory of spare parts to minimize any potential downtime.

As an industry leader, we are committed to providing high-quality and high-efficiency dry ice machines to meet various needs of our customers. Feel free to contact us for more information about dry ice machine price and technical details!