Dry Ice Pellet Making Machine

With a minimum output of 40kg/h and a maximum of 500kg/h, Shuliy dry ice pellet making machine has improved many global customers start and expance their dry ice production. We have six different model of pellet making equipment. The pellet size is 3mm-19mm, available for most industries.

Shuliy dry ice pellet making machine is available in six output sizes to produce high-quality dry ice pellets of up to 40-500 KG/hour each. It is a fully automated machine with one-touch push-button activation of all functions, which greatly increases productivity and saves on production costs. We can also provide you with more complex customized solutions, so please feel free to contact us by phone or through WhatsApp.

Dry Ice Pellet Making Machine Working Video

Dry Ice Maker Machine Introduction

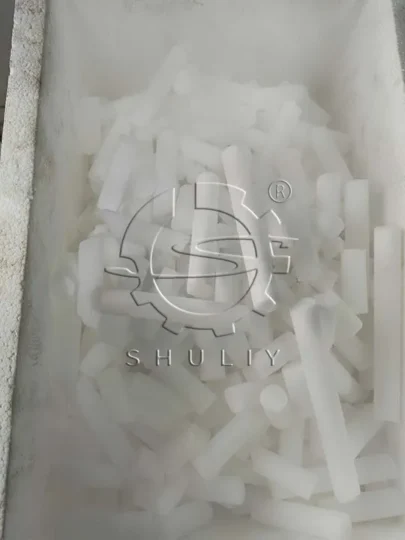

Dry ice maker machine is a specialized machine for converting liquid carbon dioxide into dry ice pellets. A dry ice pellet is a solid carbon dioxide with low temperature and non-volatile properties, which is commonly used for dry ice cleaning, low-temperature preservation cold chain transportation, stage, wedding, and other smoke effects.

Shuliy automatic dry ice maker machine produces 17 different diameters of pellets at the push of a button: from 3mm to 19mm. The machine has a high-density, fully automated dry ice production capacity with a density of up to 1550 kg/m³, which is much higher than other products in the market.

Why Choose Shuliy Dry Ice Pellet Making Machine?

- The design is more humanized. Our dry ice pellet making machine body is made of stainless steel, integrated and fully closed design, reducing the noise of the equipment when working, but also to prevent the work of the personnel of accidental touch caused by the danger, work more safely.

- We choose to use the imported original brand for the core electrical components, international brand quality assurance you can trust.

- Core module built-in design: hydraulic pump station, pellet molding module are set up inside dry ice pellet making machine built-in, this design, on the one hand, reduces the footprint of the equipment, saving space for your factory, on the other hand, also makes the dry ice production to avoid the influence of dust, which can help you to get more pure dry ice pellets.

- Touch LCD panel: easy and simple to operate, zero-based staff can also quickly start operation. The LCD panel can set the number of times of hydraulic cylinder blowing, working time and so on, which greatly reduces the operation error rate.

What’s the Application of Dry Ice Pelletizer Machine?

- Transportation and preservation: Dry ice can be used as a refrigerant to transport perishable foods and cryogenically preserved pharmaceuticals to extend shelf life.

- Manufacturing: In the manufacturing industry, dry ice pellets can be used as the raw material by dry ice blasting machine to clean high-precision instruments or stubborn stains. For example, dry ice cleaning can be used to clean food processing equipment such as stoves, conveyor belts and containers, as well as the exterior of automobiles and engine compartments.

- Stage Effects: Dry ice can be used to create smoke-like effects for stage performances, weddings, movie shoots and more.

- Research and Laboratory: Dry ice is used for laboratory freezing, sample preservation and experimental manipulation, as well as in scientific research and laboratory applications.

Technical Parameters of Dry Ice Pellet Machine for Sale

| Model | SL-50 | SL-100 | SL-150 | SL-200 | SL-300 | SL-500 |

| Capacity(kg/h) | 50 | 100 | 150 | 200 | 300 | 500 |

| Diameter(mm) | Φ3-Φ16 | Φ3-Φ19 | Φ3-Φ19 | Φ3-Φ19 | Φ3-Φ19 | Φ3-Φ19 |

| Density(kg/m³) | 1550 | 1550 | 1550 | 1550 | 1550 | 1550 |

| Conversion ratio | ≥42% | ≥42% | ≥42% | ≥42% | ≥42% | ≥42% |

| Power(kw) | 3 | 4 | 7.5 | 5.5 | 7.5 | 18.5 |

| Weight(kg) | 200 | 350 | 600 | 650 | 1200 | 2500 |

| Dimensions(cm) | 100×50×100 | 128×60×140 | 135×65×165 | 48×100×151 | 135×120×158 | 165×145×175 |

You can get the details in the above table, the first you should notice should be the dry ice production capacity.

If you are still confused about how to choose your dry ice generator machine, feel free to contact us right now, our manager will give you professional advice according to your demands.

How Long Can Dry Ice Pellets Last?

Generally, properly stored dry ice pellets will remain solid for approximately 24 to 36 hours. However, the exact amount of time dry ice pellets can be kept depends on the storage conditions and how they are packaged.

Here are some suggestions on how to maximize the shelf life of dry ice:

- Storage temperature: Store dry ice at very low temperatures, usually a freezing temperature of -78.5 degrees Celsius (-109 degrees Fahrenheit). The lower the temperature the longer the dry ice will keep.

- Packaging: Keep dry ice in insulated packaging, such as foam boxes, insulated bags, or storage boxes made for dry ice to extend its holding time.

- Airtight: If possible, try to keep dry ice in airtight containers to minimize gas release and maintain the dry ice in its solid state.

- Moisture-proof: Avoid exposing dry ice to water, which can cause it to evaporate and disappear quickly.

We Have Shipped Dry Ice Pelletizers to Every Corner of the World!

Shuliy Machinery has cooperated with many friends in the world, we shipped our dry ice generators to the US, Poland, India, Russia, Kosova, Oman, etc. A short time ago, we just exported our dry ice generator to Saudi Arabia this year. Contact us and tell your location, then we will introduce you the dry ice pelletizer machine price and the related sea freight costs.

Create Your Own Dry Ice Production Factory!

If you are looking for a nice reliable and trustworthy dry ice machine manufacturer, we are your best choice. We are not just a machine provider, we are a team who solves your problems patiently and provides you best services. Contact us today to learn more about our solutions and see how we can meet your needs!